How Gold Is Mined in South Africa – Methods, Challenges, and Modern Practices

Gold mining in South Africa is one of the most technically advanced and historically significant operations in the world. Unlike surface-level deposits found in West Africa, South African gold occurs deep underground in ancient geological formations, requiring sophisticated engineering, massive infrastructure, and strict regulatory compliance.

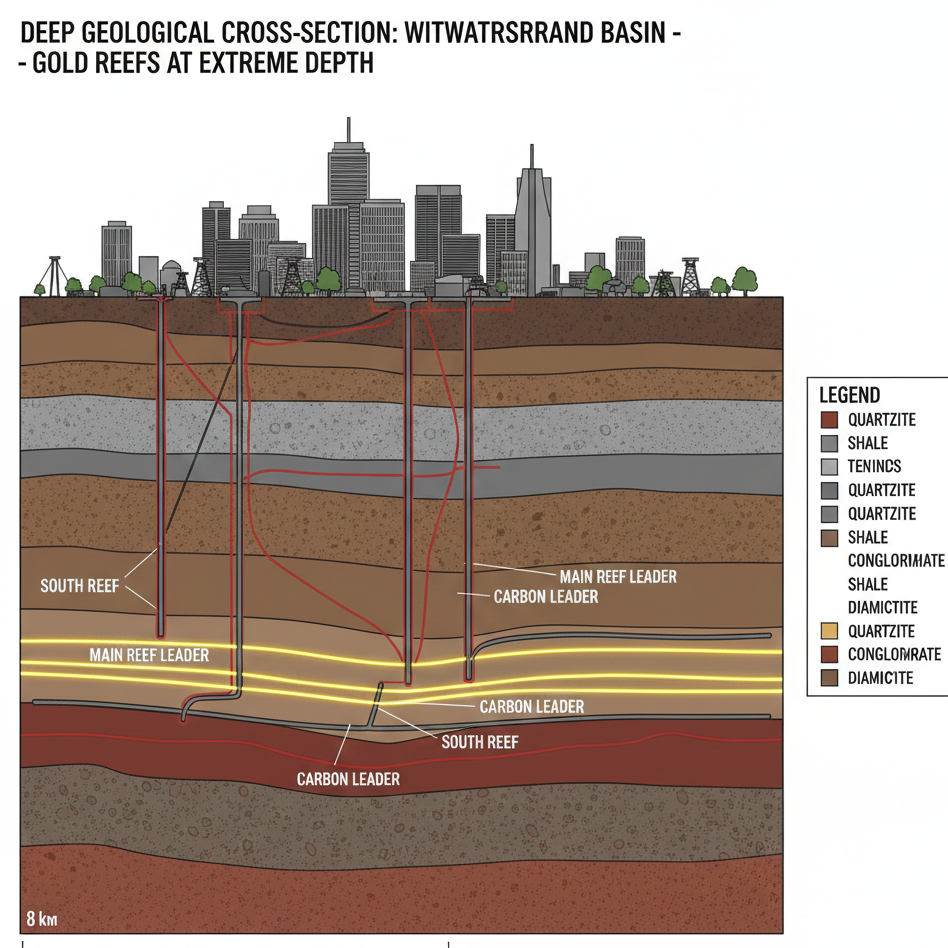

1. Geological Setting: The Witwatersrand Basin

Over 90% of South Africa’s gold comes from the Witwatersrand Basin, a 3-billion-year-old sedimentary formation that hosts gold-bearing conglomerate layers known as reefs (e.g., Carbon Leader, Ventersdorp Contact Reef). These reefs lie at depths ranging from 1 to over 4 kilometers, making South Africa home to the deepest mines on Earth.

2. Primary Mining Methods

A. Underground Hard-Rock Mining (Shaft Mining)

- Process:

- Vertical or inclined shafts are sunk to access reef levels.

- Horizontal tunnels (drives) are excavated along the reef.

- Ore is drilled, blasted, and transported to the surface via conveyors or skips.

- Used at: Mponeng (4.2 km deep), South Deep, Driefontein

- Challenges: Extreme heat (up to 60°C), rock bursts, high energy use, and ventilation demands.

B. Tailings Retreatment

- Process: Historic mine dumps (over 6 billion tonnes) are reprocessed using modern milling and cyanidation to recover residual gold.

- Advantages: Lower cost, reduced environmental impact, no new excavation.

- Operators: Sibanye-Stillwater (Elikhulu plant), Pan African Resources (Mthombo plant)

3. Processing and Refining

Once ore reaches the surface:

- Crushing & Grinding: Ore is reduced to fine particles.

- Leaching: Gold is dissolved using a cyanide solution (Carbon-in-Leach or CIL process).

- Recovery: Gold is adsorbed onto activated carbon, then stripped and electrowon.

- Smelting: Doré bars (~90% purity) are cast for refining.

- Refining: Final purification to 99.99% at the Rand Refinery in Germiston—one of the world’s largest.

4. Regulatory and Safety Framework

Mining is governed by:

- Mineral and Petroleum Resources Development Act (MPRDA)

- Mine Health and Safety Act

- Environmental Management Programmes (EMPrs)

All operations require:

- Valid mining rights from the Department of Mineral Resources and Energy

- B-BBEE compliance (minimum 30% Black ownership)

- Continuous monitoring of air quality, water use, and seismic activity

5. Challenges Facing the Industry

- Depth and Cost: Deeper mines = higher capital and operational expenses

- Energy Reliability: Load-shedding disrupts ventilation and hoisting

- Labor Relations: Historical tensions require ongoing social investment

- Declining Grades: Average ore grades have fallen below 4 g/tonne

Despite this, South Africa remains a top global producer due to its vast reserves and refining infrastructure.

6. Africa Gold Reserve’s Role

While Africa Gold Reserve does not operate mines, it sources high-purity gold exclusively from:

- Licensed industrial mines

- Registered small-scale miners in Mpumalanga and Limpopo

- Government-authorized sellers

All material is verified on-site, assayed, and documented with GPS-tagged chain-of-custody records—ensuring compliance with OECD Due Diligence Guidance and LBMA Responsible Gold standards.

Image: Field technician conducting real-time gold purity test using calibrated XRF device

Conclusion

Gold mining in South Africa is a feat of engineering, operating at extreme depths under rigorous safety and environmental standards. While challenges persist, the country’s infrastructure, expertise, and refining capacity ensure its continued role in global supply. For buyers, partnering with a professional exporter like Africa Gold Reserve provides secure access to ethically sourced South African gold—without the complexities of direct mining.

Website: africa-gold.com

Email: sales@africa-gold.com